The first pipeline in Vancouver appeared at a time when the city and the entire province were just beginning to feel the need for stable energy. It stretched across forests, mountains, and rivers, with workers navigating challenging routes daily to connect gas sources to homes and factories. Residents who witnessed its launch recall the first flow of gas reaching the city. It was a completely new experience for every Vancouverite, as the pipeline transformed life: homes received heat, factories gained energy, and Vancouver emerged as a truly modern city with its own infrastructure. This article at vancouver-future explores the construction of the pipeline, its initial deliveries, and much more.

The Birth of an Idea

The story of Vancouver’s first pipeline began with the Westcoast Transmission Company, founded by Frank McMahon in 1949. He recognized that natural gas could become the backbone of the region’s energy system, providing heat to homes and power to factories. McMahon’s vision went beyond building a pipeline for Canada; he aimed to create a route connecting northern gas sources with southern cities and the United States. Achieving this required export and import permits, along with government support from both countries. McMahon personally lobbied officials, demonstrating how the project could benefit the regional economy and energy sector.

The initial plans mapped routes through forests, rivers, and mountains, requiring meticulous calculations and preparation. Engineers surveyed the land and determined where to lay the pipes to minimize risks. Every step, from the initial idea to permits and early blueprints, laid the foundation for the project to quickly become a reality.

Pipeline Construction

Construction began in 1955 and continued until 1957. It was a massive undertaking for its time, with the pipeline stretching roughly 1,050 km (650 miles) and large enough in diameter to transport substantial volumes of natural gas south across the province and into the United States.

The work demanded complex machinery and a sizable workforce. Engineers and laborers charted routes, laid pipes, built compressor stations, and ensured the system’s integrity. Every day presented challenges, with terrain, weather, and soil conditions to consider. Workers lived in camps along the route, braving cold and rain, aware that they were creating something historically significant for the region.

Heavy equipment, including excavators, cranes, and specialized machines for welding and transporting pipes, was essential. Every operation required precision, as even minor errors could halt work or damage the system. Once the pipes were installed, engineers tested pressure and tightness along every kilometer before gas could flow. Although construction ended in 1957, the pipeline was ready well before its official launch.

Notably, over 100,000 tons of steel were used in building the first pipeline, with an average capacity of about 850 million cubic meters of gas per year. Eight compressor stations were installed along the route to maintain pressure, some of which are still operational in today’s network.

The First Gas Delivery

In 1957, gas from the Westcoast Pipeline first reached Vancouver and the southern regions of British Columbia. The pipes ran through mountains and forests, with compressor stations maintaining even pressure to ensure smooth, uninterrupted flow. Initially, deliveries went to large industrial facilities, where gas was used for heating workshops and powering production processes. Later, it extended to residential homes.

The introduction of natural gas transformed the region’s energy landscape. Vancouver residents gained reliable heating, and factories operated without interruptions, boosting productivity. For the first time, the city and surrounding areas experienced the benefits of centralized energy supply, safe and dependable even in the harshest winter months.

Operating Canada’s first major pipeline required constant monitoring. Engineers checked pressure, temperature, and pipe conditions along the entire route. Each kilometer had unique characteristics: some sections traversed challenging terrain, requiring extra supports and protection against landslides. Control centers monitored gas flow 24/7, and rapid response teams were ready for any unexpected events. The first launch became a memorable event for the entire region.

Ownership Changes and Network Expansion

In 2002, Westcoast Transmission Company was acquired by Duke Energy and later, in 2017, merged with Enbridge. This integration allowed the pipeline to become part of a broader energy network spanning regions of Canada and the United States.

The pipeline underwent gradual modernization. New compressor stations were added, sections crossing difficult terrain were reinforced, control systems updated, and uninterrupted operation ensured. This allowed gas to reach new industrial and residential areas, making the pipeline an integral part of modern infrastructure.

Impact on Vancouver

The Westcoast Pipeline played a critical role in developing British Columbia’s energy sector. It provided stable natural gas supply to Vancouver and nearby regions, allowing factories to operate smoothly and residents to enjoy heating and hot water in their homes. The regional economy benefited: businesses could plan production, new industries expanded thanks to reliable energy, and living standards improved. The pipeline became a symbol of engineering ambition and one of the region’s first large-scale projects.

Further Development of Pipelines

After the launch of the Westcoast Pipeline, Vancouver’s gas network rapidly expanded. City and industrial growth demanded new routes, leading to additional branches and local distribution systems in the 1960s and 1970s. Gas supply increased not only for factories but also for homes, with the introduction of gas stoves, meters, and modern heating.

Later, Vancouver’s system integrated with the national grid via the TransCanada Pipeline, ensuring stable supply from other regions. In the 1980s and 1990s, BC Gas (later FortisBC) managed city gas distribution, modernizing the network with automated control and safety systems.

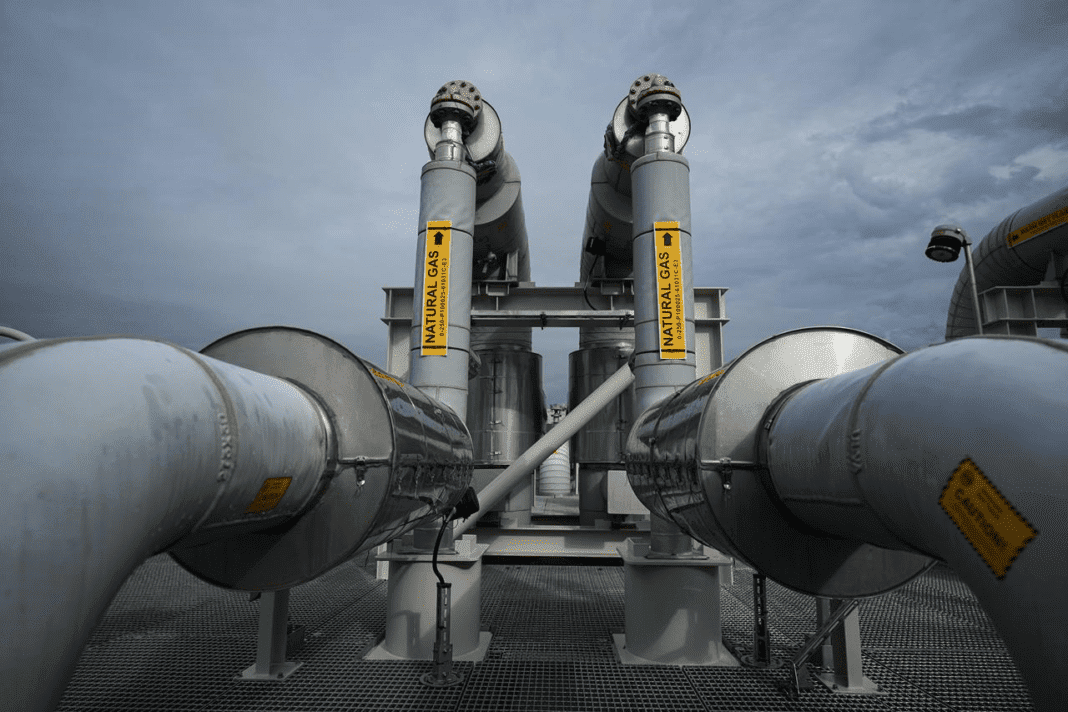

Modern Infrastructure

Today, Vancouver’s pipeline infrastructure is part of a high-tech system with real-time monitoring. FortisBC is developing the use of renewable natural gas (RNG) from biomass, reducing emissions and making the region’s energy supply greener and more sustainable.

Sources:

- https://www.renewableenergyworld.com/hydro-power/dams-civil-structures/duke-energy-completes-8-billion-acquisition-of-westcoast-energy

- https://talkingenergy.ca/stories/how-fortisbc-natural-gas-flows-your-home-now-and-renewable-energy-future

- https://yorkspace.library.yorku.ca/items/ccd43996-b664-4bc0-b17f-1fa52910313d

- https://www66.statcan.gc.ca/eng/1959/195908750845_p.%20845.pdf

- https://rbscarchives.library.ubc.ca/uploads/r/university-of-british-columbia-library-rare-books-and-special-collections/4/6/46c7bf0a153292f58a4e3a62b46d25ceaaae2e930b0c6fee347dff38bb06be49/Westcoast_Energy_Inc.pdf

- https://csegrecorder.com/articles/view/a-brief-history-of-canadas-natural-gas-production